Home > Products > Electro Permanent Lifting Magnets > HM1 – Fix Electro Permanent magnetic Beam

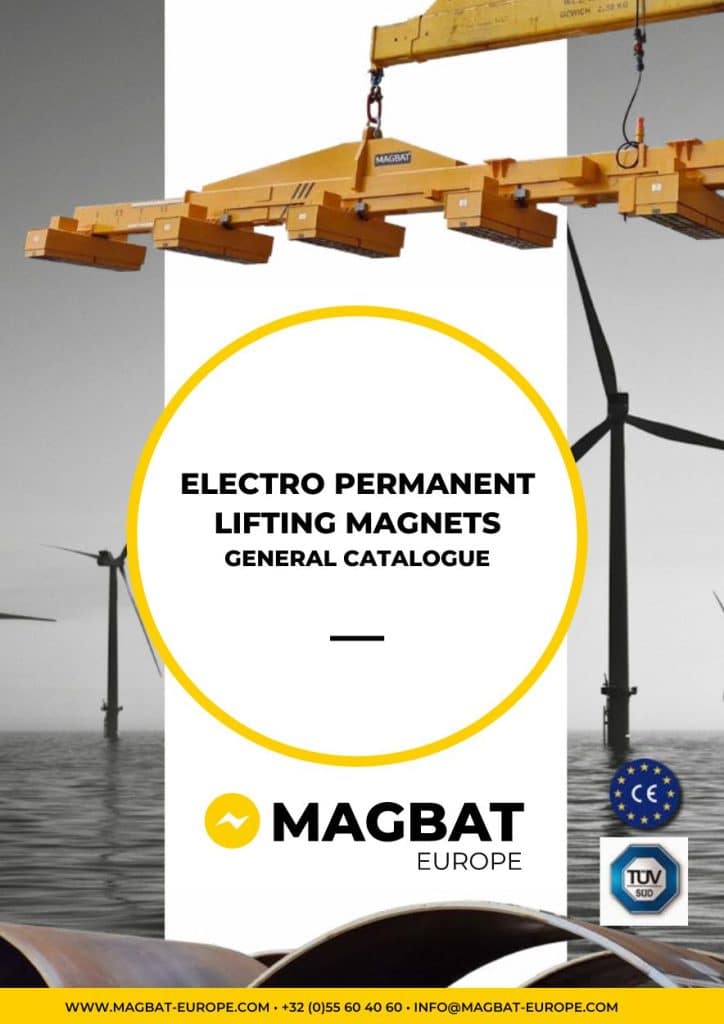

HM1 - Electro Permanent magnetic Beam

Fix electro permanent magnetic Beam

LIFTING SINGLE STEEL SHEETS

PRODUCT DESCRIPTION

The HM1 fix electro permanent magnetic beam is the economical solution to lift single steel sheets with a minimum thickness of 5 mm.

The innovative electro permanent magnetic technology provides a reliable and safe solution for heavy-duty lifting operations, making it the excellent choice for industries such as manufacturing, construction, and metalworking.

InquiryFEATURES

- Welded beam made of structural steel S355, including Chains, and lifting Ring.

- Electro permanent magnetic Modules, elastically suspended, for perfect adaptation to the steel Sheet.

- Operation by the digital push buttons on the control unit or by the standard supplied radio remote control.

- High advanced SPC-system (System Performance Check)

- Depending on the dimensions of the steel plate, a corresponding number of magnetic modules can be selected via a 4-position switch.

- The PICK-UP cycle grants the safe lifting of a SINGLE steel Sheet.

- Landing detection system to avoid accidental demagnetisation in the Air.

| Model | SWL (kg) | Min. Thickness (mm) | Width min - max (mm) | Length min - max (mm) | Qty EPM Modules | Weight (kg) |

|---|---|---|---|---|---|---|

| HM1-03-025 | 2.500 | 3 | 500 - 2.000 | 500 - 3.000 | 4 | 450 |

| HM1-04-040 | 4.000 | 5 | 500 - 3.200 | 250 - 4.000 | 4 | 450 |

| HM1-06-030 | 3.000 | 5 | 500 - 3200 | 500 - 6.000 | 6 | 900 |

| HM1-06-060 | 6.000 | 5 | 500 - 3.200 | 500 - 6.000 | 6 | 1.000 |

| HM1-06-090 | 9.000 | 5 | 500 - 3.200 | 500 - 6.000 | 6 | 1.100 |

| HM1-06-240 | 24.000 | 8 | 580 - 3.200 | 500 - 6.000 | 6 | 1.600 |

| HM1-09-050 | 5.000 | 5 | 500 - 3.200 | 2350 - 9000 | 8 | 1.200 |

| HM1-09-080 | 8.000 | 5 | 500 - 3.200 | 2350 - 9000 | 8 | 1.300 |

| HM1-09-100 | 10.000 | 5 | 500 - 3.200 | 2350 - 9000 | 8 | 1.400 |

| HM1-09-120 | 12.000 | 5 | 500 - 3.200 | 2350 - 9000 | 8 | 1.500 |

| HM1-09-160 | 16.000 | 5 | 500 - 3.200 | 2350 - 9000 | 8 | 1.600 |

| HM1-12-050 | 5.000 | 5 | 500 - 3.200 | 5.000 - 12.000 | 10 | 1.600 |

| HM1-12-080 | 8.000 | 5 | 500 - 3.200 | 5.000 - 12.000 | 10 | 1.800 |

| HM1-12-100 | 10.000 | 5 | 500 - 3.200 | 5.000 - 12.000 | 10 | 2.000 |

| HM1-12-150 | 15.000 | 5 | 500 - 3.200 | 5.000 - 12.000 | 10 | 2.200 |

| HM1-12-200 | 20.000 | 5 | 500 - 3.200 | 5.000 - 12.000 | 10 | 2.400 |

| HM1-12-240 | 24.000 | 5 | 500 - 3.200 | 6.000 - 12.000 | 12 | 2.800 |

| HM1-16-100 | 10.000 | 5 | 500 - 3.500 | 2.900 - 16.000 | 12 | 2.600 |

| HM1-16-140 | 14.000 | 5 | 500 - 3.500 | 2.900 - 16.000 | 12 | 2.700 |

| HM1-16-200 | 20.000 | 5 | 500 - 3.500 | 2.900 - 16.000 | 12 | 2.900 |

| HM1-16-240 | 24.000 | 5 | 500 - 3.500 | 2.900 - 16.000 | 12 | 3.000 |

Download our brochure

Gain valuable insights into the benefits, applications, and technical specifications about our products. Fill in the form below to receive the brochure directly to your email.