Magnetic quick change systems enable efficient mould and die changes, enhancing productivity in injection molding and punch presses. Our system, leading in electro permanent magnet technology, revolutionizes the way industries handle dies and molds, enhancing safety, energy efficiency, and operational productivity.

> Discover our Magnetic Quick Change Systems for Dies or Magnetic Quick Change Systems for Moulds. <

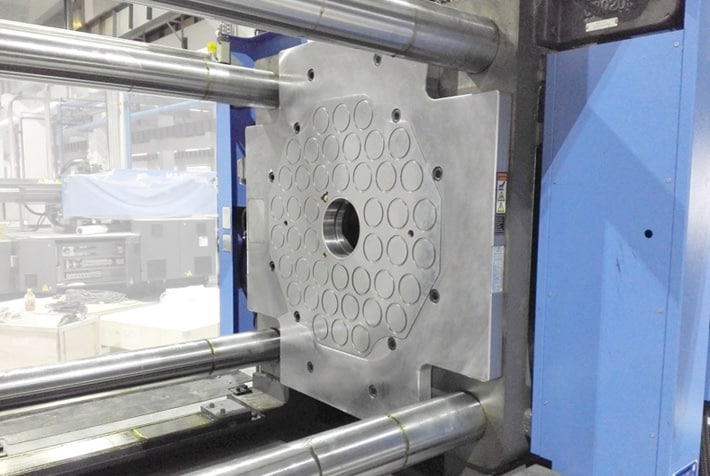

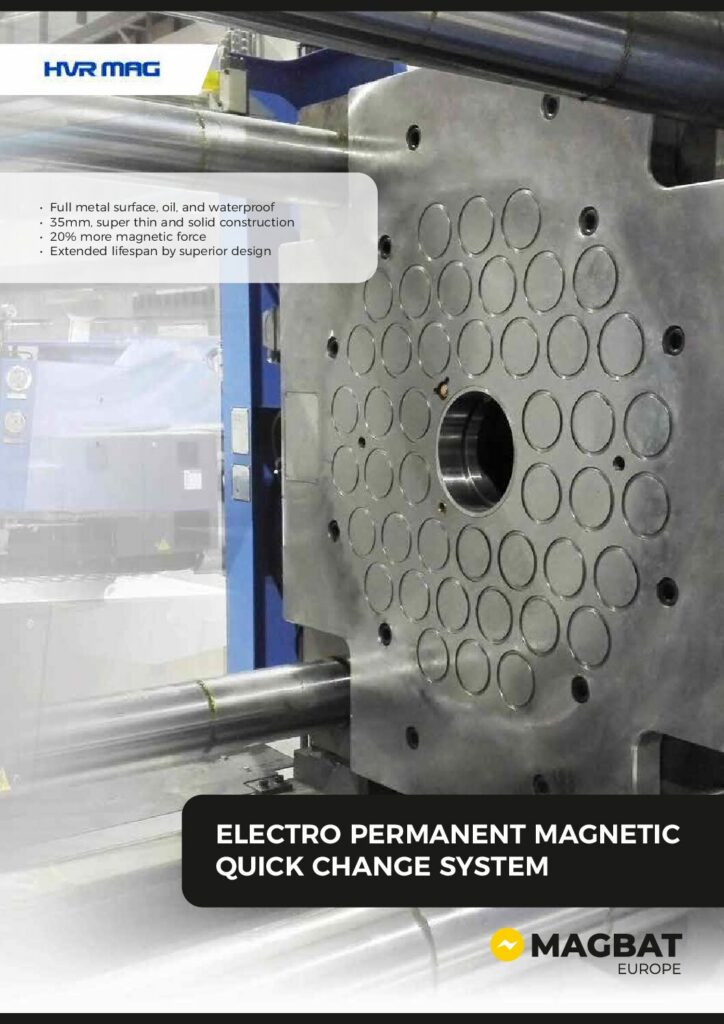

Magnetic Quick Change Systems for Injection Moulds

Magnetic clamping plates reduce mold changeover time by 90%, enabling safe and ergonomic mold changes by a single operator. No mold modifications are needed, as any shape or size can be safely clamped.

Magnetic Quick Change Systems for Dies

Magnetic clamping plates can decrease die changeover time by 90%, allowing one operator to safely and ergonomically perform the task.

HQMC Magnetic Clamping System (Quick Mold/Die Change System)

Our Magnetic Clamping System uses optimised unique electro permanent magnetic clamping technology, for the clamping of moulds and dies for plastic injection moulding machines and metal stamping presses.

Reduce change time of mould or dies to 3 minutes

The change time of moulds and tools is drastically reduced up to 95%, with a maximum change time of 3 minutes. This system consists of 2 magnetic plates, fixed and stationary, man-machine interface, electrical control box. Size and geometric shape of the magnetic plates can be freely designed as requested by the customer.

The magnetic quick change system is perfectly suited for a range of sectors, including automotive manufacturing, precision engineering, injection molding, metal stamping, and steel production, our system streamlines complex processes, significantly improving production time and output quality.

Download our brochure

Gain valuable insights into the benefits, applications, and technical specifications about our products. Fill in the form below to receive the brochure directly to your email.

Achievements

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.