Home > Products > Electro Permanent lifting Magnets > 9 Safety Features

9 Safety Features

THE SAFEST LIFTING MAGNET IN THE WORLD.

1

ELECTRO PERMANENT MAGNETIC TECHNOLOGY

The electric current is solely utilized to reverse the magnetic field, while the permanent magnets generate the actual force. In case of a power outage, the magnetic force remains permanently present, ensuring 100% safety.

2

SAFETY FACTOR 3:1

For safe lifting, it is important to account for a potential air gap between the magnet's contact surface and the steel being lifted. That's why all our magnets are designed with a minimum safety factor of 3:1, measured at an air gap of 0.4 mm.

3

LANDING DETECTION

An inductive proximity switch is utilized to detect the suspension of the magnet in the air, effectively preventing accidental demagnetization.

4

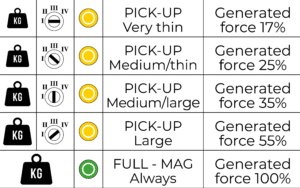

PICK-UP CYCLE

The lifting process occurs in two phases. Initially, the workpiece is lifted at a lower predetermined force (PICK-UP), immediately followed by the activation of FULLMAG, which applies the full force (100% of the total force).

5

2 BUTTON OPERATION

To initiate the demagnetization cycle, the remote control requires the consecutive pressing of two buttons (SAFE + DEMAG).

6

RADIO REMOTE CONTROL

The magnet is operated from a safe distance. The operator should not come in the immediate vicinity of the load.

7

LAMP BLOCK

The status of the magnet is visually indicated by a clear LED lamp block. The load may only be moved when the green lamp lights up continuously!

8

INSTRUCTION PANEL

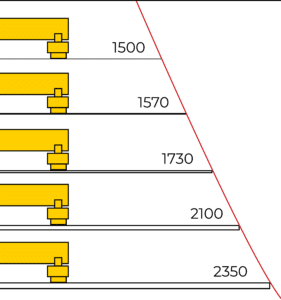

Containing clear safety instructions for the user regarding:

- Maximum load weight based on material thickness

- Maximum wing based on material deflection.

9

SPC-SYSTEM (System Performance Check)

The electronic system continuously monitors the proper functioning of the magnet. Any abnormal situation is reported immediately and indicated by an error code on the help screen. In this way, errors can be immediately analysed and resolved.