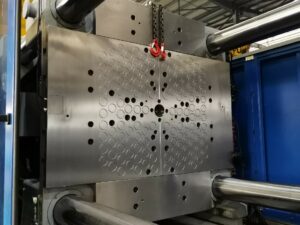

At PLASMIR, a plastics processing company in Spain, we recently installed an electro-permanent magnetic quick mold change system on a 1500-ton CHEN HSONG injection molding machine. Fully integrated according to the EUROMAP 70.1 standard, this upgrade delivers a powerful leap forward in productivity, operator safety, and operational flexibility.

Up to 85% faster mold changes

The magnetic system allows operators to clamp and unclamp molds in seconds. What used to take several minutes — sometimes longer — with manual or hydraulic clamping, now takes a fraction of the time. With a single push of a button, the mold is clamped securely, across the entire surface.

Energy-saving and operator-friendly

Because the machine no longer needs to cool down during mold changes, cycle times stay short and energy costs drop. In addition, operators no longer need to climb into the machine to manually secure molds, which significantly improves ergonomics and safety.

Unmatched mold flexibility

The magnetic system adapts to any mold shape or size — no modifications required. Even larger molds can now be safely clamped on smaller machines, giving PLASMIR greater flexibility across their production lines.

At a glance: key benefits for PLASMIR

-

85% reduction in mold change time

-

Lower energy consumption and operating costs

-

Safer, more ergonomic work environment

-

Full-surface clamping without mechanical stress points

-

Compatible with any mold shape or dimension

-

No modifications needed to existing molds

This installation perfectly illustrates how electro-permanent magnetic technology is reshaping the way modern injection molding facilities operate.

Curious how it could work in your plant? Get in touch — we’d be happy to show you.