Electro permanent magnetic chucks for workholding offer secure and efficient clamping for milling, turning, and grinding operations, enhancing productivity and precision.

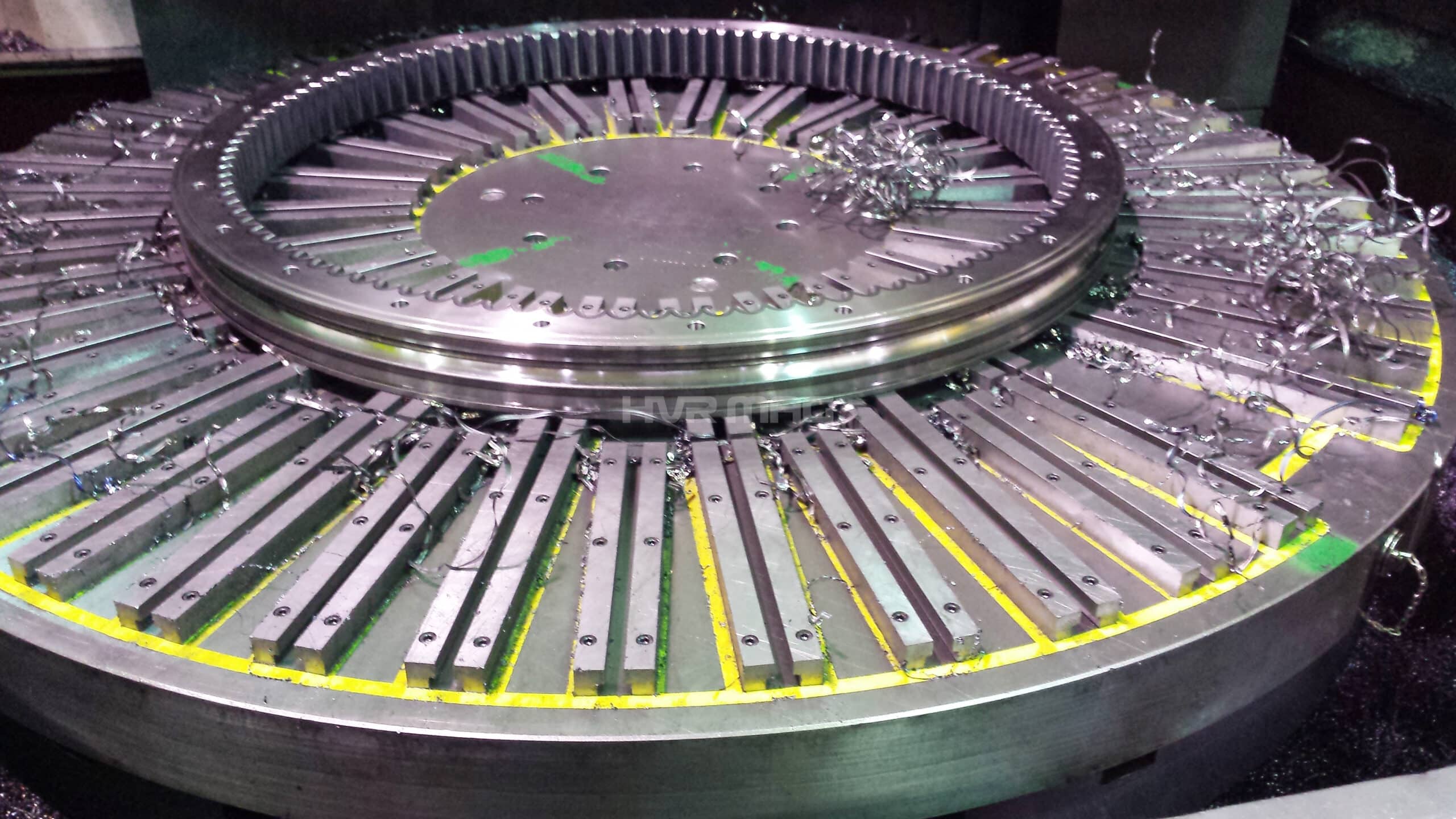

Magnetic Chucks for Lathes

Electro Permanent Magnetic (EPM) Lathe chucks provide a solution by clamping the workpiece from its base surface. This setup allows uninterrupted tool paths and enables complete machining in a single setup.

Magnetic Chucks for Grinding Machines

Electro-permanent magnetic chucks offer a superior solution for grinding and spark erosion machines. Their short current pulse and permanent magnet force prevent overheating and maintain precision.

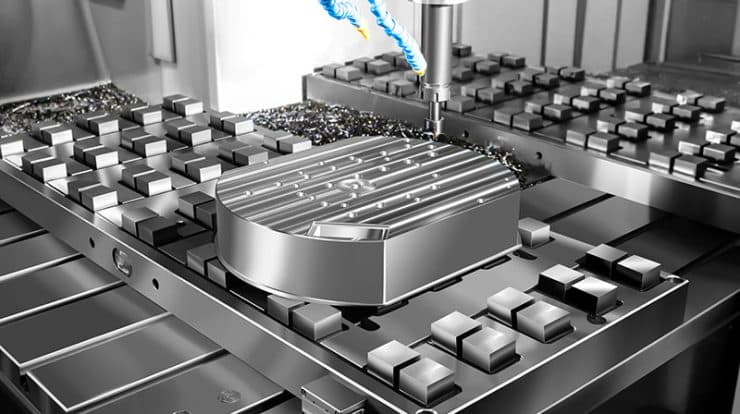

Magnetic Chucks for Milling Machines

Electro-permanent magnet tables for milling machines have a chessboard pattern of square pole plates with alternating N/S poles. They feature fixed and mobile pole extensions that adapt to the workpiece shape, allowing tension-free clamping. This setup enables efficient machining on five sides, minimizing repositioning.

Benefits of magnetic chucks

Adopting magnetic chucks into your workflow brings several different benefits:

- Quick and efficient clamping and unclamping: decreases setup time, which leads to increased production rates and less downtime.

- Exceptional precision: serve to reduce the risk of workpiece distortion. Force distribution over the entire workpiece, as opposed to specific points, guarantees integrity preservation and dimensional accuracy.

- Need minimal power: making them energy efficient and a conscientious choice for those dedicated to sustainable manufacturing practices.

In conclusion, the integration of magnetic chucks into your workflow can significantly boost the overall efficiency of your operations, providing not just a faster and more precise system, but also a more eco-friendly solution in today’s sustainability-focused industry.

Download our brochure

Gain valuable insights into the benefits, applications, and technical specifications about our products. Fill in the form below to receive the brochure directly to your email.

Achievements

Different kinds of magnetic chucks

The versatility of magnetic chucks is highlighted in the varying types available, each designed for specific applications. Understanding these types is essential for selecting the right chuck for your needs.

1. PERMANENT MAGNETIC CHUCKS

Permanent magnetic chucks rely on internal magnets to generate a stable magnetic field. Once activated by a simple lever mechanism, they maintain a constant hold—no electricity required. Compact, cost-effective, and easy to use, they are ideal for precision tasks on smaller grinders and EDM machines. While their holding force is limited compared to other systems, they offer a practical solution where space and budget matter more than brute strength. Less suited for heavy milling, but perfect for fine, repetitive operations.

2. ELECTRO PERMANENT MAGNETIC CHUCKS

Electro permanent magnetic chucks combine the best of both worlds: the safety of permanent magnets with the controllability of electromagnets. A short electrical pulse is enough to activate or deactivate the magnetic field—no continuous power is required during operation.

This technology offers high clamping force with zero energy consumption during machining, making it both powerful and energy-efficient. It’s especially valuable in applications where workpieces must remain securely fixed—even during power outages.

The ability to switch quickly between clamping and unclamping also speeds up changeovers, improving productivity. With their strong grip and stability, electro permanent chucks are ideal for demanding milling, grinding, and heavy-duty machining tasks.

3. MILLING MACHINES

Magnetic chucks for milling machines make sure you can work with precision, enhance the use and take it to a next level. These chucks, often in electro-permanent configurations, offer a chessboard pattern of square poles that, in combination with pole extentions, can adapt to various workpiece shapes, ensuring tension-free clamping.

This adaptability is crucial for milling operations, allowing for machining on multiple sides of a workpiece without needing to reposition it. The result is a seamless workflow that enhances productivity and ensures immaculate precision with every cut.

GRINDING MACHINES

Using magnetic chucks for grinding machines will make working with grinding machines a true joy. These chucks provide a stable platform that prevents overheating and maintains accuracy, essential for operations as delicate as grinding and spark erosion.

The durability and precision offered by magnetic chucks in grinding applications ensure that even the finest details are maintained, leading to flawless finishes and superior quality of the final product.

4. LATHES

Clamping the workpiece from its base, the magnetic chucks for lathes of Magbat Europe make sure tool paths will not be interrupted and machining will be complete in a single setup.

The uniform clamping provided by magnetic chucks minimizes vibration during lathe operations, resulting in improved machining tolerances and extended tool life. This not only boosts productivity but also ensures a higher quality of the machined components.